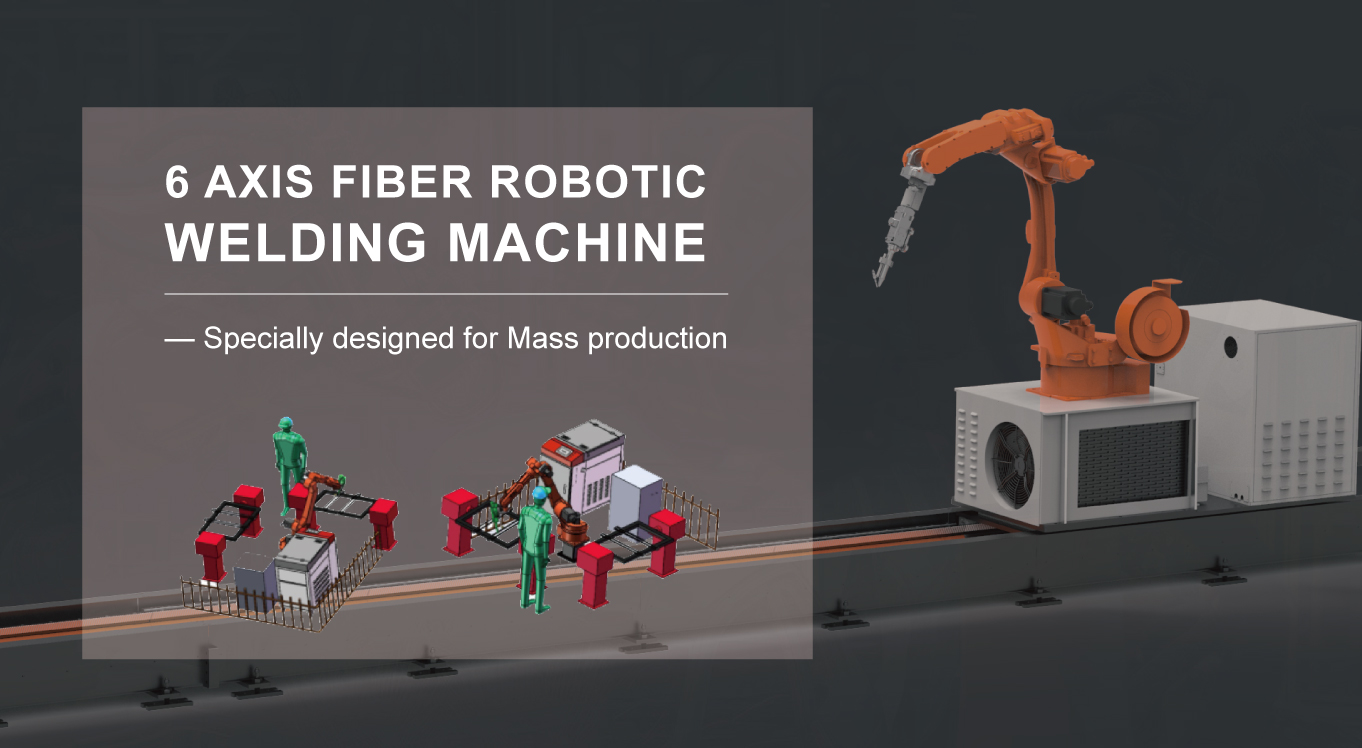

High Precision 6 Axis Robotic Automatic Fiber Laser Welding Machine

Zida Zazida:

1. Kugwiritsa ntchito kayendedwe ka robotic, koyenera kuwotcherera kwa malo akuluakulu, kungakhale kulumikiza kwazitsulo zisanu ndi chimodzi.

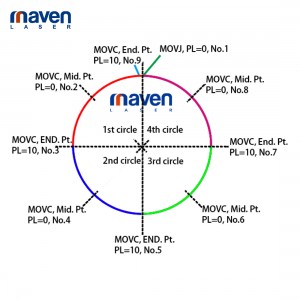

2. Kodi kuwotcherera mu malo aliwonse, moona kuzindikira kuwotcherera basi wa trajectory iliyonse mu danga.

3. Kubwerezabwereza kubwerezabwereza, kungathe kubwereza kuwotcherera nthawi zambiri popanda cholakwika, khalidwe la weld ndilokhazikika.

4. Iwo akhoza m'malo ntchito Buku, ndipo akhoza laser weld minda zovuta ndi zoopsa.

Malo ofunsira:

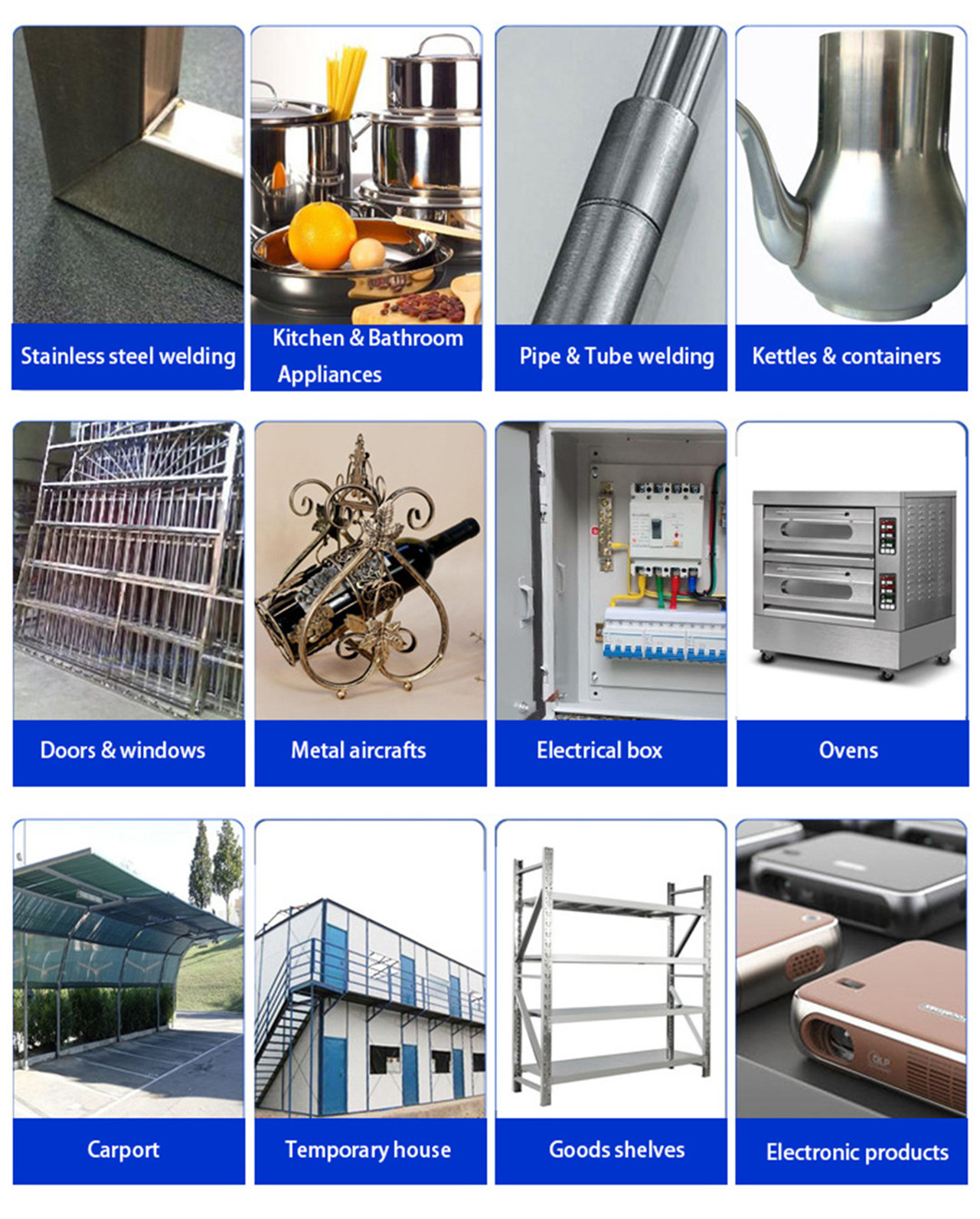

Auto thupi, galimoto zitsulo mbale, mbale zowalamulira, zovuta ndi zovuta kuwotcherera minda, zigawo zikuluzikulu microelectronic, mbali mwatsatanetsatane, apamwamba kalasi zigawo digito, zolumikizira CHIKWANGWANI chamawonedwe, zipangizo zachipatala, kuwotcherera nkhungu lalikulu, akamaumba jekeseni ndi kuwotcherera ena.

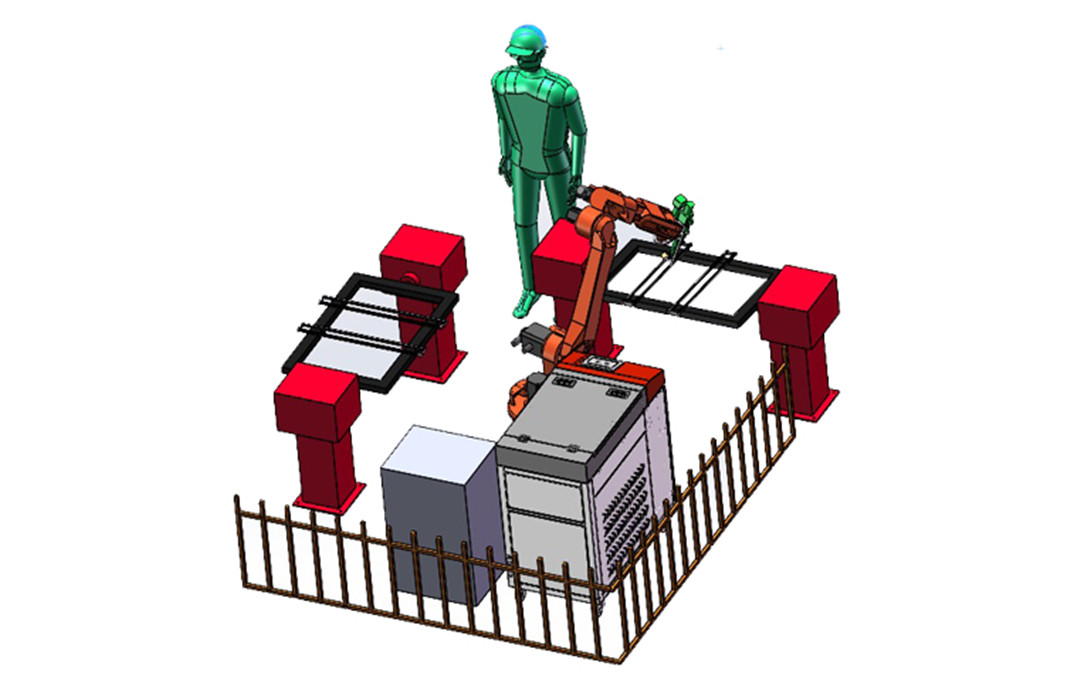

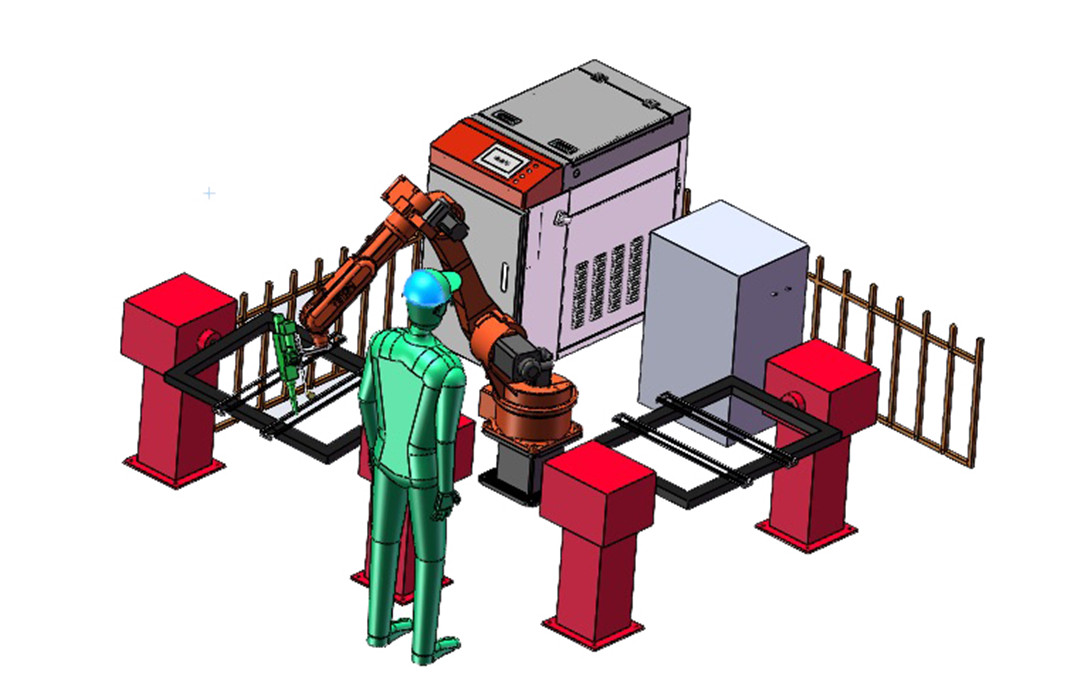

ROBOTI LASER kuwotcherera MACHINE

PROFESSIONAL WElding SOLUTION

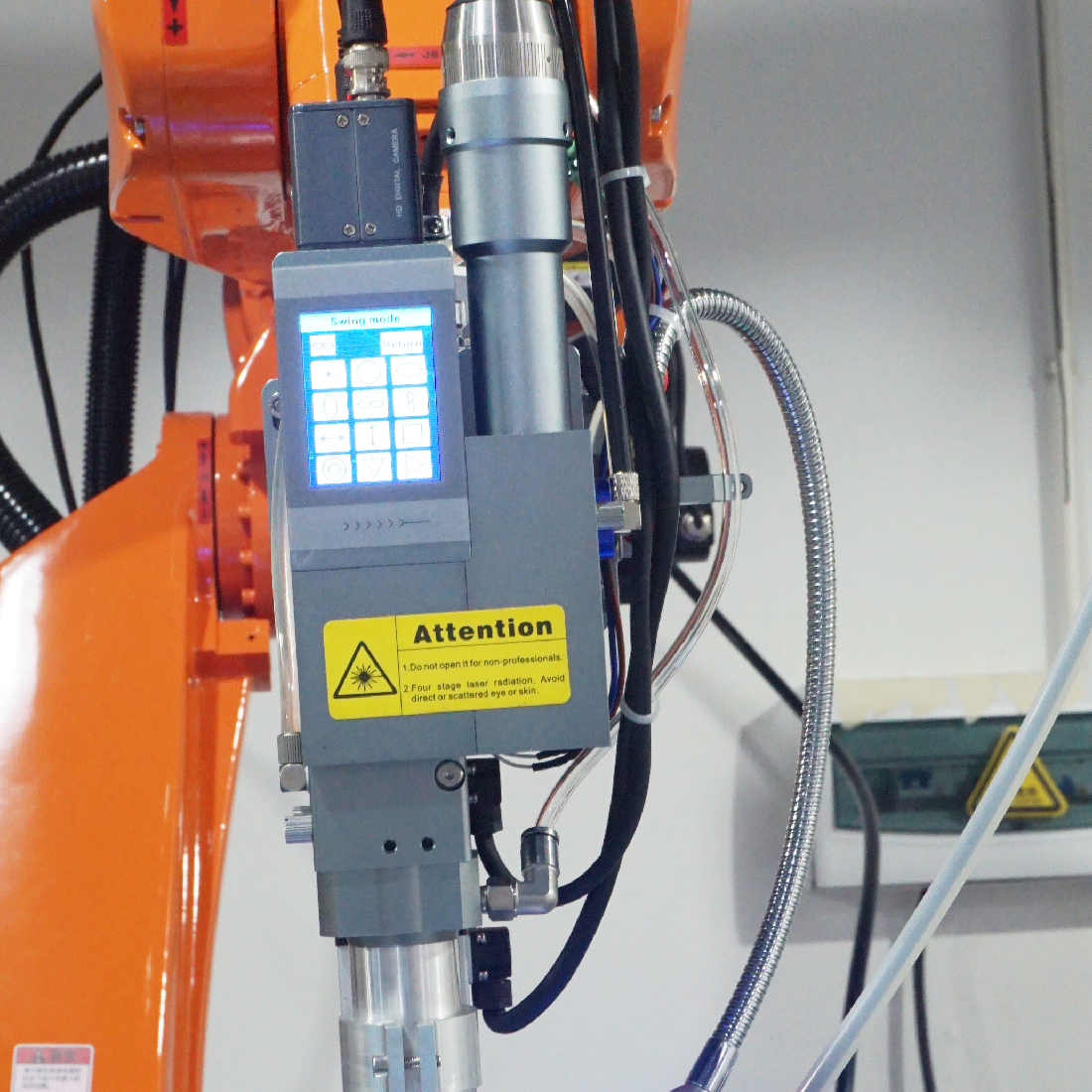

Wire Feeder ndi Welding Anakhazikika pa Control Pedal

0.08mm Kuyika kwa Robot Kulondola

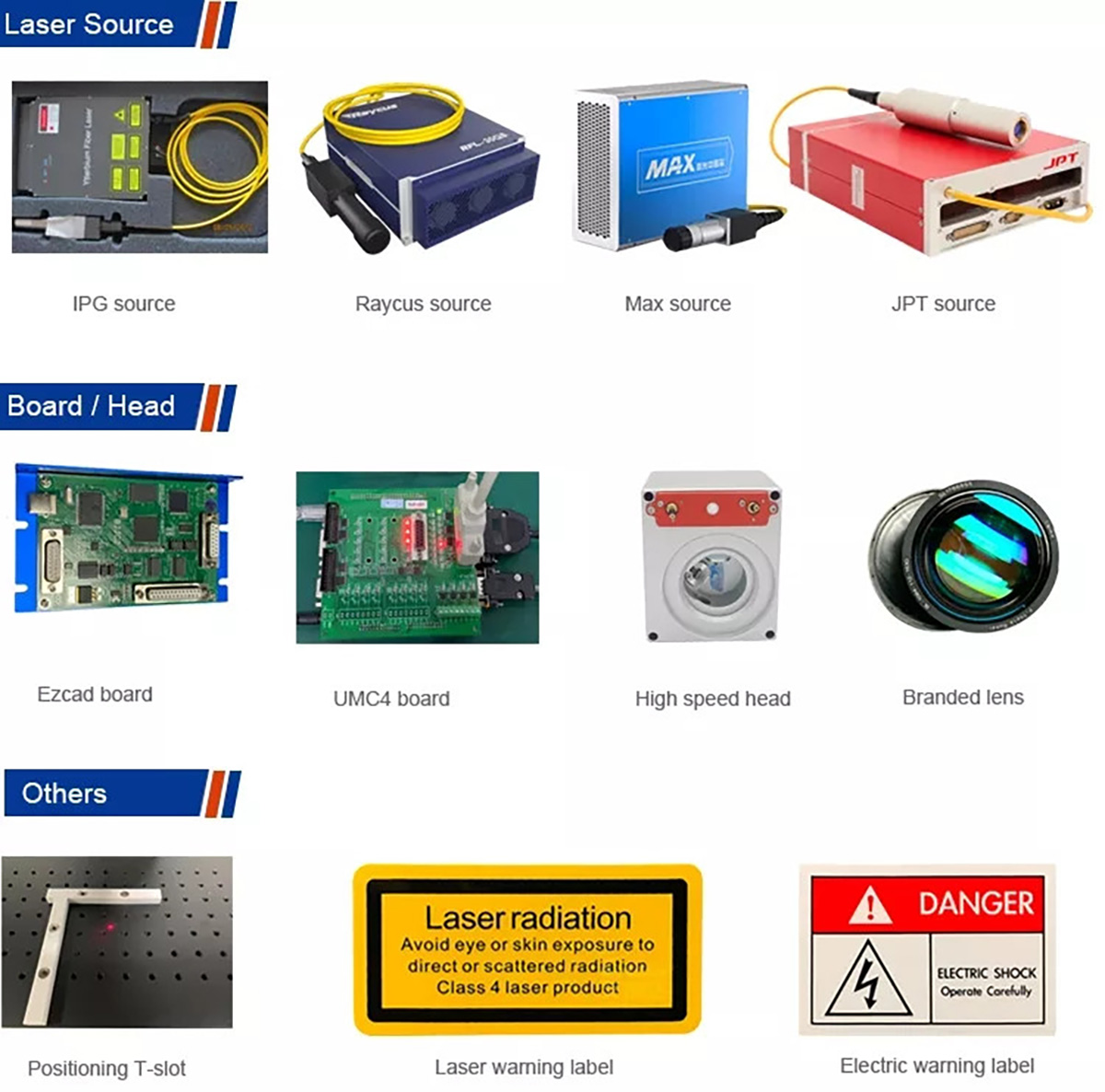

Raycus Max JPT IPG Laser Source Optional

Kusintha Kwadongosolo Kwadongosolo Lonse

| Dzina lazogulitsa | Makina Owotcherera a Robot Automatic LaserMLA-W-A01 |

| Wavelength | 1070+/- 10 nm |

| Mphamvu ya Laser | 1000W 1500W 2000W 3000W |

| Kusintha Mphamvu | 10-100% |

| Utali wa Fiber | Standard 10m kapena Fotokozani |

| Njira Zogwirira Ntchito | CW/Pulse |

| Speed Range | 0-120 mm |

| Weld Makulidwe | 0.5-6 mm |

| Kuwotcherera Gap Chofunikira | <1 mm |

| Kusinthasintha pafupipafupi | 20KHZ pa |

| Yatsani/zimitsa Nthawi | 20 Ife |

| Kutentha kwa Ntchito | 15-35 ℃ |

| Magetsi | 220V/50HZ/30A |

| Njira Zozizira | Madzi Ozizira Okhazikika |

| Kukula Kwa Makina | 990*540*1030 mm |

ZOsavuta KUGWIRITSA NTCHITO

Chowongolera chogwiritsa ntchito mwaubwenzi chothandizirana mosavuta ndi malangizo opangidwa ndi fiber laser kuwotcherera

KUSINTHA KWA ULAMULIRO

Kuphatikizika kwa nduna zowongolera ndikuwongolera ntchito yodyetsa waya. Ndipo mphamvu ya laser imatha kukwera ndikugwa pang'onopang'ono kuti ipewe kuwotcha. Kukwera pang'onopang'ono ndi kugwa kumakhala kopindulitsa kwambiri pakuwotcherera mbale zopyapyala. Wowongolera akamaliza, nthawi zambiri zimakhala zosavuta kuwotcherera m'mbale.

LASE INTERGRATUION

Kuwonjezera pa kusintha magawo kuwotcherera mu dongosolo laser. Ilinso ndi ntchito zamtundu uliwonse wowunikira mawonekedwe, kusintha kwamadzi amagetsi, ndi chikumbutso chodziwikiratu kuteteza mandala.

KUGWIRITSA NTCHITO

Integrated kuwotcherera mutu, CCD pamutu, mphamvu chosinthika, auto kuganizira, ntchito yabwino.

ZOsavuta KUGWIRITSA NTCHITO

Mabatani a pendant yophunzitsa ndi osavuta komanso osavuta kumva, ndipo pulogalamu yophunzitsira imatha kuphunzira ndikugwiritsa ntchito mwachangu. Ngati ntchitoyo ili yolakwika, makinawo amangoyima kuti apewe ngozi ya kuwonongeka kwa zida.

GWIRITSANI NTCHITO MOGWIRITSA NTCHITO

Ikakonzedwa, imatha kugwiritsidwa ntchito nthawi zonse. MavenLaser Robot Arm imathandizira maola 24 ogwira ntchito mosalekeza mwachangu komanso kuthamanga kwambiri. Kugwiritsa ntchito kwathunthu, loboti imatha kumaliza ntchito ya anthu opitilira 2-3 patsiku.

MTENGO WOTSIKA

Kuyika ndalama kamodzi, phindu la nthawi yayitali. Moyo wautumiki wa loboti ya MavenLaser ndi maola 80,000, omwe ndi ofanana ndi zaka zopitilira 9 za maola 24 osasokonezedwa. Zimapulumutsa kwambiri ndalama zogwirira ntchito ndi ndalama zoyendetsera antchito, ndipo zimathetsa mavuto monga kuvutika kulemba anthu ntchito.

WOTETEZA NDI WOdalilika

Dzanja la loboti la MavenLaser lili ndi njira zoteteza chitetezo cha photoeletric. Zinthu zakunja zikalowa m'malo ogwirira ntchito, zimatha kudzidzimutsa ndikuyimitsa ntchito kuti zisawonongeke mwangozi.

MPHAMVU YOTETEZEKA NDI MPENDO

MavenLaser makina opangira makina opangira makina ndi osavuta komanso owongolera pang'ono, opanda phokoso, mkono wopepuka komanso wamphamvu wa loboti, kugwiritsa ntchito mphamvu pang'ono, saxing mphamvu komanso kuteteza chilengedwe.

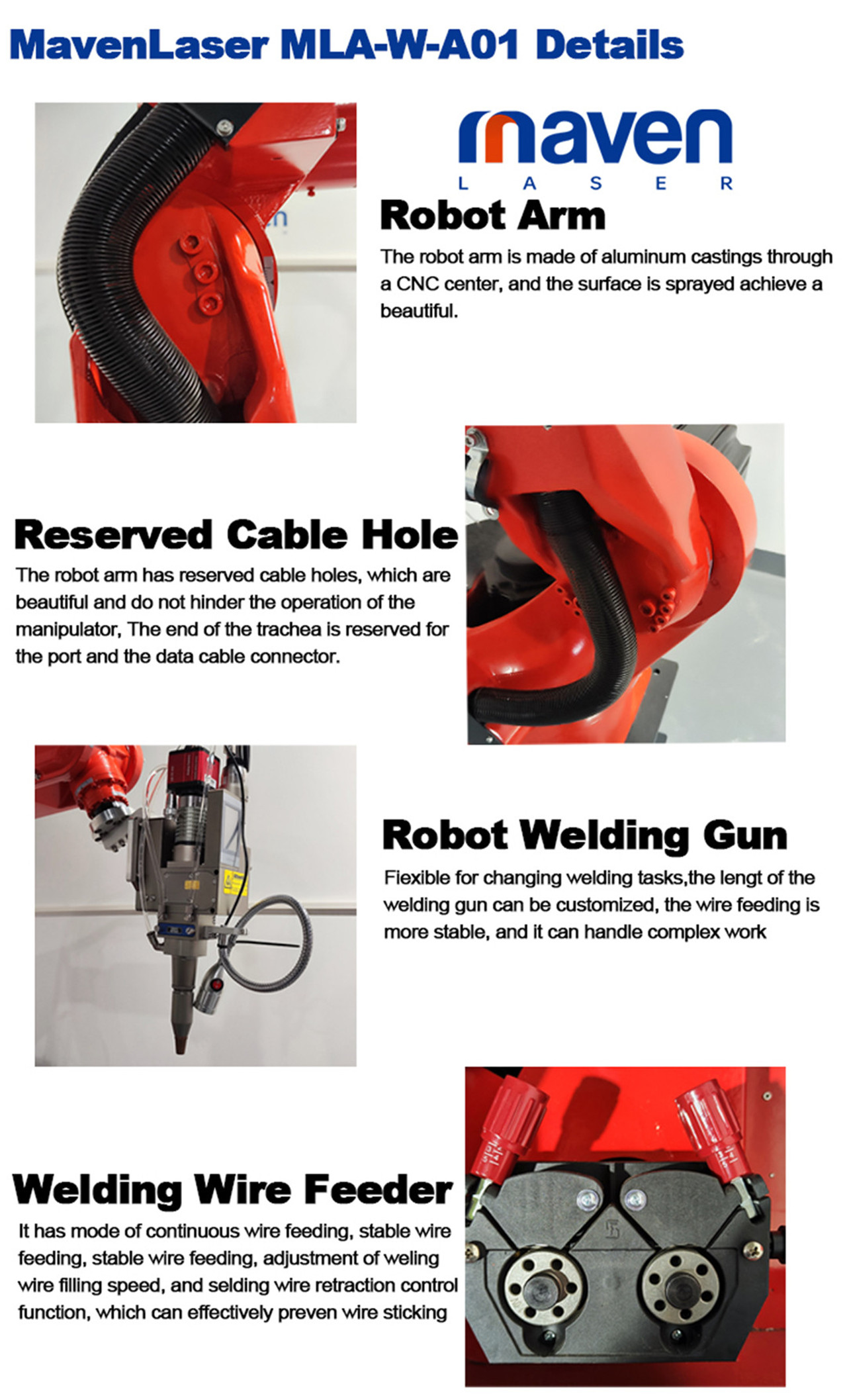

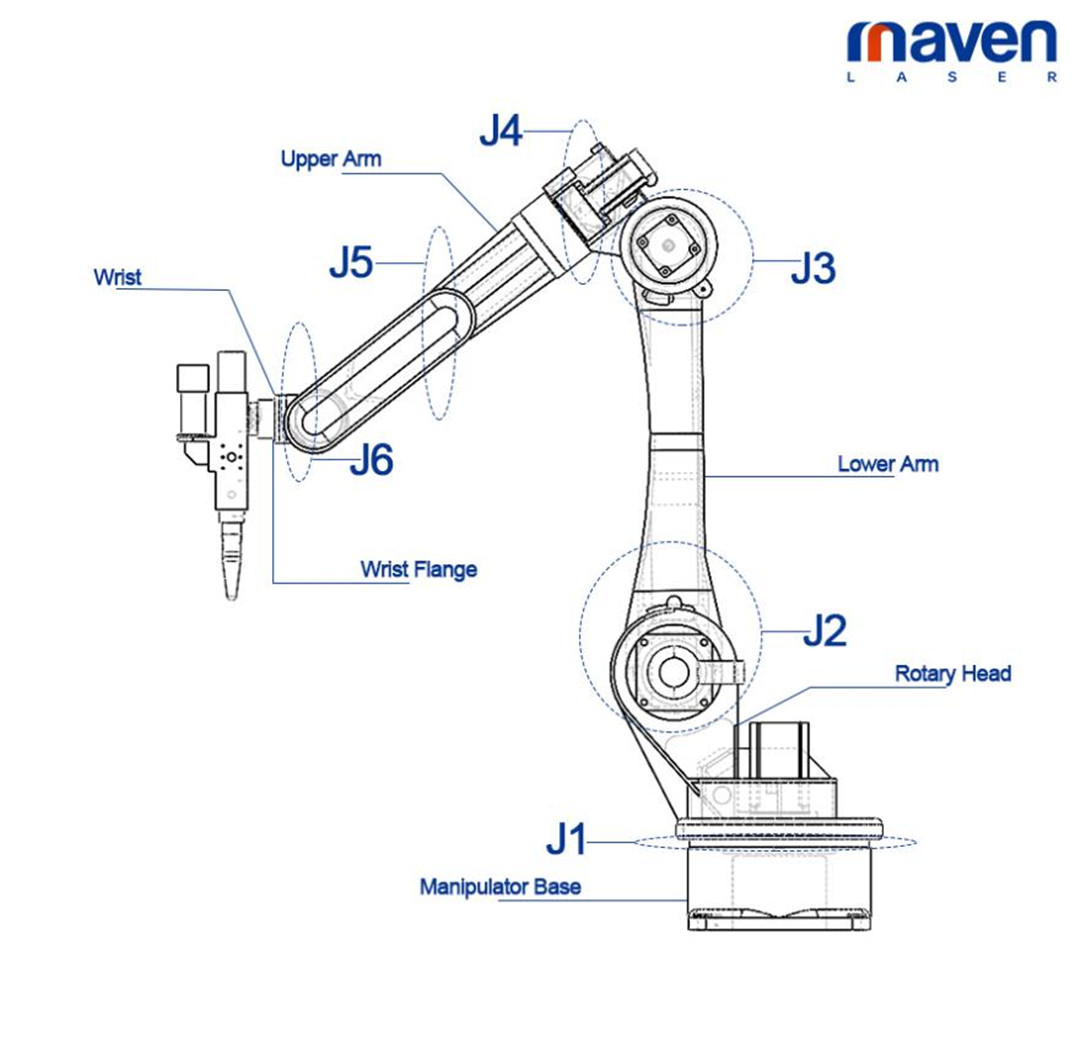

Robot Arm

Dzanja la loboti limapangidwa ndi aluminium castings kudzera pakatikati pa CNC, ndipo pamwamba pake amapopera amapeza kukongola.

Reserved Cable Hole

Mkono wa robot wasungira mabowo a chingwe, omwe ndi okongola ndipo nit amalepheretsa kugwira ntchito kwa manipulator, mapeto a trachea amasungidwa ku doko ndi cholumikizira chingwe cha data.

Mfuti Yowotcherera Roboti

Zosinthika posintha ntchito zowotcherera, kutalika kwa mfuti yowotcherera kumatha kusinthidwa, kudyetsa waya kumakhala kokhazikika, ndipo kumatha kugwira ntchito zovuta.

Welding Wire Feeder

Ili ndi njira yodyetsera mawaya mosalekeza, kudyetsa mawaya okhazikika, kudyetsa waya wokhazikika, kusinthika kwa liwiro lodzaza waya, komanso kugulitsa ntchito yowongolera mawaya, yomwe imatha kuletsa waya kumamatira.

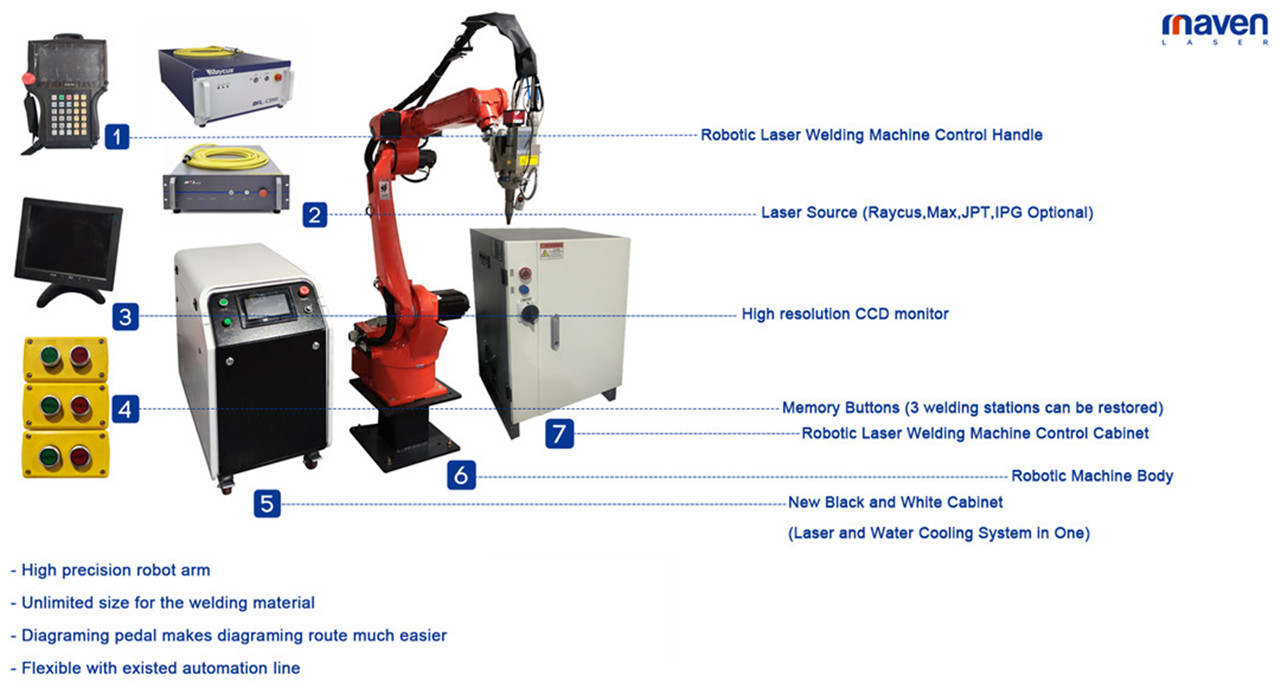

● Gwero la Laser(Raycus,Max,JPT,IPG Mwasankha)

● Kuwunika kwapamwamba kwa CCD

● Mabatani a Memory(mawotchi atatu atha kubwezeretsedwa)

● Cabinet Yatsopano Yakuda ndi Yoyera(Laser ndi Water Cooling System mu Imodzi)

● Robotic Machine Body

● Robotic Laser Welding Machine Control Cabinet

● Dzanja la loboti lolondola kwambiri

● Kukula kopanda malire kwa zinthu zowotcherera

● Kuyika ma pedal kumapangitsa njira yojambulira mosavuta

● Kusinthasintha ndi chingwe chodzipangira chokha

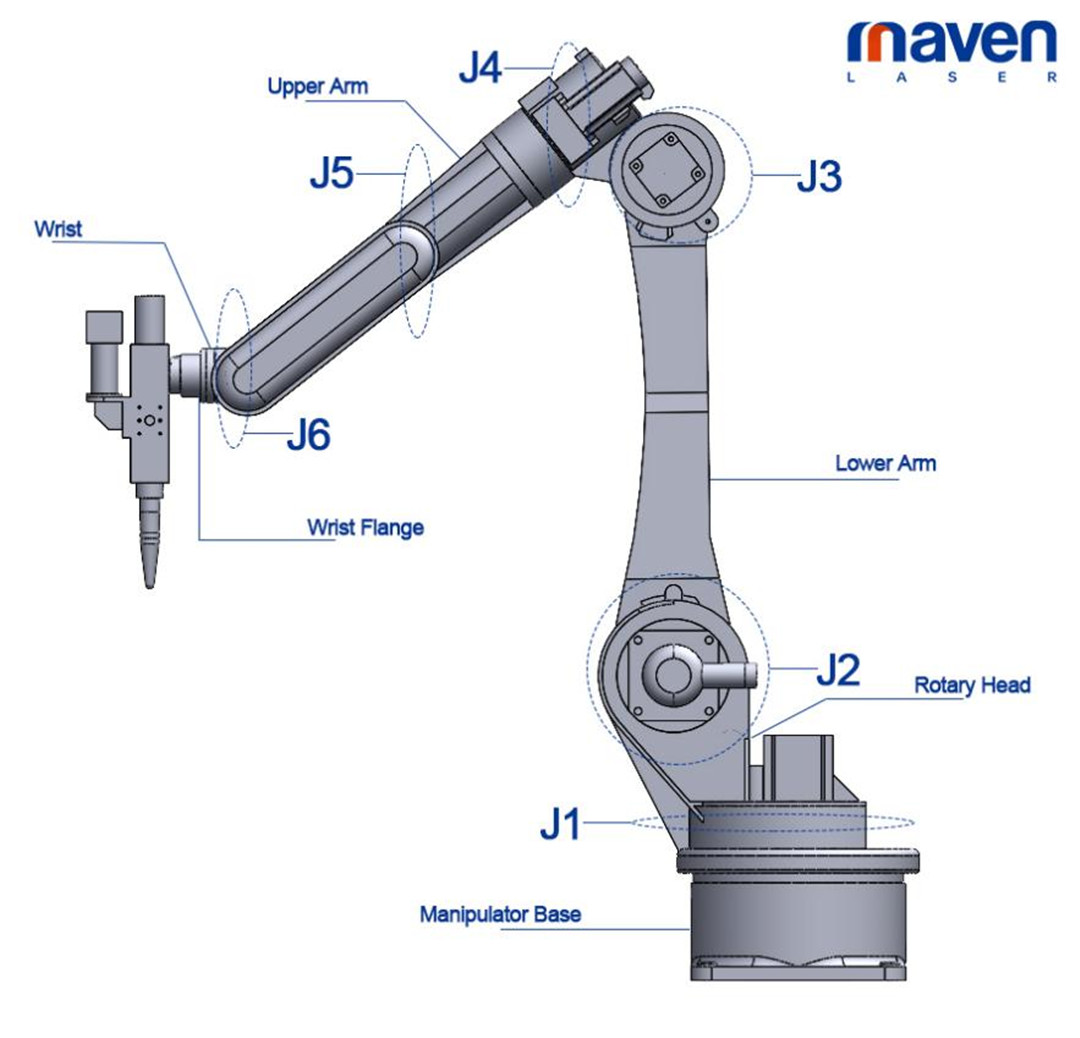

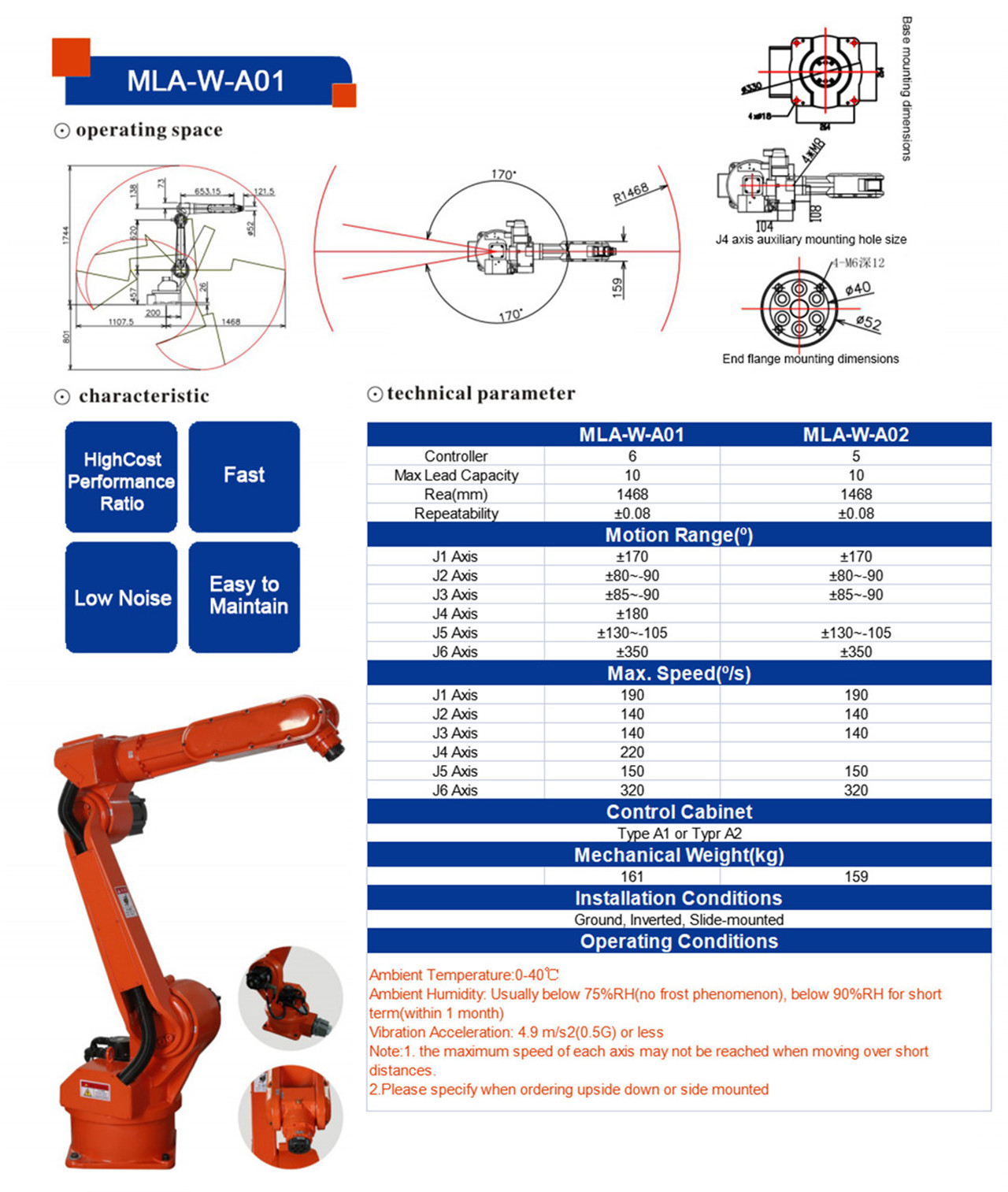

| MLA-W-A01 | MLA-WA02 | |

| Wolamulira | 6 | 5 |

| Max Kutsogolera Mphamvu | 10 | 10 |

| Uwu (mm) | 1468 | 1468 |

| Kubwerezabwereza | ± 0.08 | ± 0.08 |

| Mtundu Woyenda (°) | ||

| j1 gawo | ± 170 | ± 170 |

| j2 gawo | ± 80 ~ 90 | ± 80 ~ 90 |

| j3 gawo | ± 85 ~ 90 | ± 85 ~ 90 |

| j4 gawo | ± 180 |

|

| j5 gawo | ± 130 ~ 105 | ± 130 ~ 105 |

| j6 gawo | ± 350 | ± 350 |

| Max. Liwiro(°/s) | ||

| j1 gawo | 190 | 190 |

| j2 gawo | 140 | 140 |

| j3 gawo | 140 | 140 |

| j4 gawo | 220 |

|

| j5 gawo | 150 | 150 |

| j6 gawo | 320 | 320 |

| Control Cabinet | ||

| Type A1 kapena Type A2 | ||

| Mechanical Weight(kg) | ||

|

| 161 | 159 |

| Mikhalidwe yoyika | ||

| Ground, Inverted, Slide-mounted | ||

| Kagwiritsidwe Ntchito | ||

Kutentha kozungulira: 0-40 ℃

Chinyezi Chozungulira: Nthawi zambiri pansi pa 75% RH (palibe chochitika chisanu), pansi pa 90% RH kwakanthawi kochepa (mkati mwa mwezi umodzi)

Kuthamanga kwa Vibration:: 4.9 m/s2(0.5G) kapena kuchepera

Zindikirani: 1.kuthamanga kwambiri kwa axis iliyonse sikungatheke pamene mukuyenda pamtunda waufupi.

2.Chonde tchulani pamene mukuyitanitsa mozondoka kapena mbali yokwera

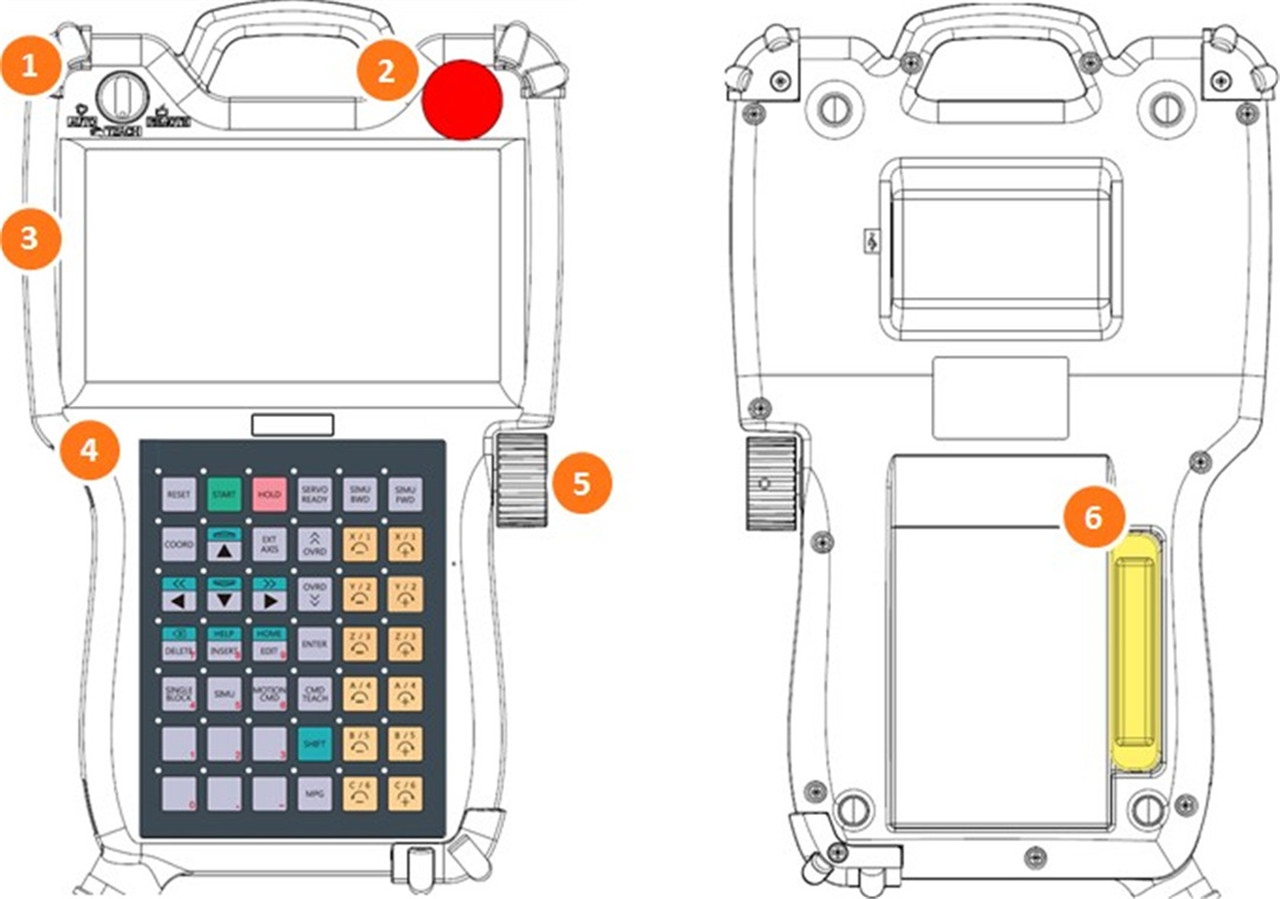

1. Kusintha kwa mawonekedwe

2. Kuyimitsa Mwadzidzidzi

3. Kuwonetsa Screen

4. Makiyi Akuthupi

5. MPG (Manuel Pulse Generator)

6. Kuthandizira Chipangizo