M'zaka zaposachedwa, chifukwa chakukula kwachangu kwamakampani opanga mphamvu zatsopano, kuwotcherera kwa laser kwalowa mwachangu mumakampani onse amagetsi atsopano chifukwa cha zabwino zake mwachangu komanso zokhazikika. Pakati pawo, zida zowotcherera za laser ndizomwe zimagwiritsidwa ntchito kwambiri pamakampani onse atsopano amagetsi.

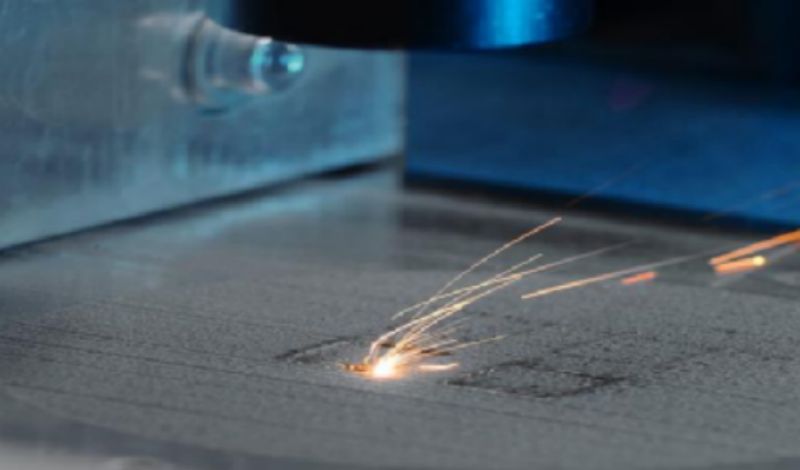

Kuwotcherera kwa laserchakhala chosankha choyamba m'mbali zonse za moyo chifukwa cha liwiro lake, kuya kwakukulu, ndi kupunduka kochepa. Kuyambira pa ma welds mpaka ma welds a matako, kumanga ndi kusindikiza,laser kuwotchereraimapereka kulondola kosayerekezeka ndi kuwongolera. Zimagwira ntchito yofunika kwambiri pakupanga mafakitale ndi kupanga, kuphatikiza mafakitale ankhondo, chithandizo chamankhwala, zakuthambo, zida zamagalimoto za 3C, zitsulo zamakina zamakina, mphamvu zatsopano ndi mafakitale ena.

Poyerekeza ndi ukadaulo wina wowotcherera, kuwotcherera kwa laser kuli ndi zabwino ndi zovuta zake zapadera.

Ubwino:

1. Kuthamanga kwachangu, kuya kwakukulu ndi mapindikidwe ang'onoang'ono.

2. Kuwotcherera kungathe kuchitidwa pa kutentha kwabwino kapena pansi pazikhalidwe zapadera, ndipo zipangizo zowotcherera zimakhala zosavuta. Mwachitsanzo, mtengo wa laser sumayandama pamalo opangira ma elekitiroma. Ma laser amatha kuwotcherera mu vacuum, mpweya kapena malo ena a gasi, ndipo amatha kuwotcherera zinthu zomwe zimadutsa mugalasi kapena zowonekera ku mtengo wa laser.

3. Imatha kuwotcherera zida zodzitchinjiriza monga titaniyamu ndi quartz, komanso imatha kuwotcherera zida zofananira ndi zotsatira zabwino.

4. Pambuyo poyang'ana laser, mphamvu yamagetsi imakhala yochuluka. Chiŵerengerocho chikhoza kufika pa 5: 1, ndipo chimatha kufika pa 10: 1 powotchera zipangizo zamphamvu kwambiri.

5. Micro kuwotcherera akhoza kuchitidwa. Pambuyo poyang'ana mtengo wa laser, malo ang'onoang'ono amatha kupezeka ndipo akhoza kuikidwa molondola. Itha kugwiritsidwa ntchito pamisonkhano ndi kuwotcherera zazing'ono ndi zazing'ono zogwirira ntchito kuti mukwaniritse zopanga zopanga zokha.

6. Imatha kuwotcherera madera ovuta kufikako ndikuchita kuwotcherera mtunda wautali osalumikizana, ndi kusinthasintha kwakukulu. Makamaka m'zaka zaposachedwa, ukadaulo wa YAG laser processing watengera ukadaulo wotumizira ma fiber optical, zomwe zapangitsa ukadaulo wowotcherera wa laser upitilize kulimbikitsidwa ndikugwiritsa ntchito.

7. Mtsinje wa laser ndi wosavuta kugawanika mu nthawi ndi malo, ndipo matabwa angapo amatha kukonzedwa m'malo angapo nthawi imodzi, kupereka zinthu zowotcherera molondola.

Chilema:

1. Kulondola kwa msonkhano wa workpiece kumafunika kukhala apamwamba, ndipo malo a mtengo pa workpiece sangathe kupatuka kwambiri. Izi ndichifukwa choti kukula kwa mawanga a laser pambuyo poyang'ana kumakhala kochepa ndipo msoko wowotcherera ndi wopapatiza, zomwe zimapangitsa kuti zikhale zovuta kuwonjezera zida zachitsulo zodzaza. Ngati kulondola kwa msonkhano wa workpiece kapena malo olondola a mtengowo sikukwaniritsa zofunikira, zolakwika zowotcherera zimatha kuchitika.

2. Mtengo wa lasers ndi machitidwe okhudzana ndi okwera, ndipo ndalama za nthawi imodzi ndizokulu.

Common kuwotcherera laser zolakwikamu kupanga batri ya lithiamu

1. Kuwotcherera porosity

Zowonongeka zofala mulaser kuwotchererandi pores. Dziwe loyengedwa ndi zitsulo ndi lakuya komanso lopapatiza. Panthawi yowotcherera ndi laser, nayitrogeni amalowa m'dziwe losungunuka kuchokera kunja. Pakuzizira ndi kulimba kwachitsulo, kusungunuka kwa nayitrogeni kumachepa ndi kuchepa kwa kutentha. Pamene chitsulo chosungunuka cha dziwe chikazizira kuti chiyambe kunyezimira, , kusungunuka kumatsika kwambiri komanso mwadzidzidzi. Panthawi imeneyi, mpweya wochuluka udzayamba kupanga thovu. Ngati liwiro loyandama la thovuli ndi locheperapo liwiro la crystallization zitsulo, pores adzapangidwa.

Mu ntchito mu lifiyamu batire makampani, nthawi zambiri timapeza kuti pores ndi makamaka zotheka kuchitika pa kuwotcherera cha elekitirodi zabwino, koma kawirikawiri zimachitika pa kuwotcherera kwa elekitirodi negative. Izi ndichifukwa choti ma elekitirodi abwino amapangidwa ndi aluminiyamu ndipo ma elekitirodi olakwika amapangidwa ndi mkuwa. Panthawi yowotcherera, aluminiyamu yamadzimadzi pamtunda imasungunuka mpweya wamkati usanasefukire, kulepheretsa mpweya kusefukira ndikupanga mabowo akuluakulu ndi ang'onoang'ono. Small stomata.

Kuwonjezera pa zomwe zimayambitsa pores zomwe tazitchula pamwambapa, pores amaphatikizanso mpweya wakunja, chinyezi, mafuta apamwamba, ndi zina zotero.

Nanga bwanji kuchepetsa kupezeka kwa kuwotcherera pores?

Choyamba, kalekuwotcherera, madontho a mafuta ndi zonyansa pamwamba pa zinthu zomwe zimalowa ziyenera kutsukidwa nthawi; popanga mabatire a lithiamu, kuyang'anira zinthu zomwe zikubwera ndizofunikira.

Chachiwiri, kutuluka kwa mpweya wotetezera kuyenera kusinthidwa malinga ndi zinthu monga liwiro la kuwotcherera, mphamvu, malo, ndi zina zotero, ndipo sayenera kukhala yaikulu kapena yaying'ono kwambiri. Kuthamanga kwa chovala choteteza kuyenera kusinthidwa malinga ndi zinthu monga mphamvu ya laser ndi malo owonetsetsa, ndipo sayenera kukhala yokwera kwambiri kapena yotsika kwambiri. Maonekedwe a mphuno yotetezera chovala ayenera kusinthidwa molingana ndi mawonekedwe, malangizo ndi zinthu zina za weld kotero kuti chovala chotetezera chikhoza kuphimba malo otsekemera.

Chachitatu, kuwongolera kutentha, chinyezi ndi fumbi mumlengalenga mumsonkhanowu. Kutentha kozungulira ndi chinyezi kudzakhudza chinyezi pamwamba pa gawo lapansi ndi mpweya woteteza, zomwe zidzakhudzanso kubadwa ndi kuthawa kwa nthunzi yamadzi mu dziwe losungunuka. Ngati kutentha kozungulira ndi chinyezi ndipamwamba kwambiri, padzakhala chinyezi chochuluka pamwamba pa gawo lapansi ndi mpweya woteteza, kutulutsa nthunzi wambiri wamadzi, zomwe zimapangitsa pores. Ngati kutentha kozungulira ndi chinyezi ndizochepa kwambiri, padzakhala chinyezi chochepa pamwamba pa gawo lapansi ndi mpweya wotetezera, kuchepetsa kubadwa kwa nthunzi yamadzi, potero kuchepetsa pores; aloleni ogwira ntchito kuti azindikire mtengo wamtengo wapatali wa kutentha, chinyezi ndi fumbi pa siteshoni yowotcherera.

Chachinayi, njira yosinthira mtengo imagwiritsidwa ntchito kuchepetsa kapena kuchotsa pores mu kuwotcherera kwakuya kwa laser. Chifukwa cha kuwonjezereka kwa kugwedezeka pa kuwotcherera, kugwedezeka kwa mtengowo ku msoko wowotcherera kumayambitsa kusungunuka mobwerezabwereza kwa gawo la weld seam, komwe kumatalikitsa nthawi yokhalamo zitsulo zamadzimadzi mu dziwe lowotcherera. Pa nthawi yomweyi, kupatuka kwa mtengowo kumawonjezeranso kutentha kwa gawo lililonse. Chiŵerengero chakuya ndi m'lifupi cha weld chimachepetsedwa, chomwe chimapangitsa kuti pakhale buluu, potero kuchotsa pores. Kumbali ina, kugwedezeka kwa mtengo kumapangitsa kuti dzenje laling'ono ligwedezeke moyenerera, lomwe lingaperekenso mphamvu yotsitsimutsa padziwe lowotcherera, kuonjezera convection ndi kugwedeza kwa dziwe lotsekemera, ndikukhala ndi zotsatira zopindulitsa pakuchotsa pores.

Chachisanu, kugunda pafupipafupi, kugunda pafupipafupi kumatanthawuza kuchuluka kwa ma pulse omwe amaperekedwa ndi mtengo wa laser pa nthawi ya unit, zomwe zingakhudze kuyika kwa kutentha ndi kudzikundikira kwa kutentha mu dziwe losungunuka, kenako kumakhudza gawo la kutentha ndi gawo loyenda mumadzi osungunuka. dziwe. Ngati kugunda kwachulukidwe kumakhala kokwera kwambiri, kumayambitsa kutentha kwakukulu mu dziwe losungunuka, zomwe zimapangitsa kutentha kwa dziwe losungunuka kukhala lokwera kwambiri, kutulutsa nthunzi wachitsulo kapena zinthu zina zomwe zimakhala zosasunthika pakutentha kwambiri, zomwe zimapangitsa kuti pores. Ngati kugunda kwafupipafupi kumakhala kotsika kwambiri, kungayambitse kutentha kosakwanira mu dziwe losungunuka, kuchititsa kutentha kwa dziwe losungunuka kukhala lotsika kwambiri, kuchepetsa kusungunuka ndi kuthawa kwa gasi, zomwe zimapangitsa pores. Nthawi zambiri, kugunda kwamtima kuyenera kusankhidwa molingana ndi makulidwe a gawo lapansi ndi mphamvu ya laser, ndikupewa kukhala okwera kwambiri kapena otsika kwambiri.

Mabowo owotcherera (kuwotcherera kwa laser)

2. Weld spatter

Sipatter yomwe imapangidwa panthawi yowotcherera, kuwotcherera kwa laser kumakhudza kwambiri mawonekedwe a weld, ndikuipitsa ndikuwononga mandala. The ntchito ambiri ndi motere: pambuyo kuwotcherera laser anamaliza, particles ambiri zitsulo amaoneka pamwamba pa zinthu kapena workpiece ndi kumamatira pamwamba pa zinthu kapena workpiece. Kuchita mwachilengedwe kwambiri ndikuti pakuwotcherera munjira ya galvanometer, pakatha nthawi yogwiritsa ntchito magalasi oteteza a galvanometer, pamakhala maenje owundana pamwamba, ndipo maenjewa amayamba chifukwa cha kuwotcherera sipatha. Patapita nthawi yaitali, n'zosavuta kutsekereza kuwala, ndipo padzakhala mavuto kuwotcherera kuwala, zotsatira mndandanda wa mavuto monga wosweka kuwotcherera ndi pafupifupi kuwotcherera.

Kodi zomwe zimayambitsa kukwapula ndi chiyani?

Choyamba, kachulukidwe ka mphamvu, kuchulukitsitsa kwamphamvu kwamphamvu, ndikosavuta kupanga sipatter, ndipo sipatter imagwirizana mwachindunji ndi kuchuluka kwa mphamvu. Ili ndi vuto lazaka zana. Osachepera mpaka pano, makampaniwa sanathe kuthetsa vuto la splashing, ndipo angangonena kuti wachepetsedwa pang'ono. M'makampani a batri a lithiamu, splashing ndiye vuto lalikulu la batire lalifupi, koma silinathe kuthetsa chomwe chimayambitsa. Zotsatira za spatter pa batri zitha kuchepetsedwa kuchokera pakuwona chitetezo. Mwachitsanzo, kuzungulira kwa madoko ochotsa fumbi ndi zotchingira zoteteza zimawonjezedwa mozungulira mbali yowotcherera, ndipo mizere ya mipeni ya mpweya imawonjezedwa mozungulira kuteteza kuwononga kwa sipatter kapena kuwonongeka kwa batire. Kuwononga chilengedwe, katundu ndi zigawo zikuluzikulu kuzungulira siteshoni kuwotcherera tinganene kuti zatha njira.

Ponena za kuthetsa vuto la spatter, tinganene kuti kuchepetsa mphamvu zowotcherera kumathandiza kuchepetsa siponji. Kuchepetsa liwiro la kuwotcherera kungathandizenso ngati kulowa sikukwanira. Koma muzofunikira zina zapadera, zimakhala ndi zotsatira zochepa. Ndi njira yomweyi, makina osiyanasiyana ndi magulu osiyanasiyana azinthu amakhala ndi zotsatira zosiyana zowotcherera. Choncho, pali lamulo losalembedwa mu makampani atsopano a mphamvu, gawo limodzi la magawo owotcherera pa chipangizo chimodzi.

Chachiwiri, ngati pamwamba pa zinthu zomwe zakonzedwa kapena zogwirira ntchito sizinayeretsedwe, madontho amafuta kapena zoipitsa zingayambitsenso kuphulika kwakukulu. Panthawiyi, chinthu chophweka ndi kuyeretsa pamwamba pa zinthu zowonongeka.

3. High reflectivity laser kuwotcherera

Nthawi zambiri, kuwunikira kwakukulu kumatanthawuza kuti zinthu zomwe zimapangidwira zimakhala ndi zopinga zazing'ono, zosalala bwino, komanso kutsika pang'ono kwa ma lasers apafupi ndi infrared, zomwe zimatsogolera kutulutsa kwakukulu kwa laser, komanso chifukwa ma lasers ambiri amagwiritsidwa ntchito. moyima Chifukwa cha zinthu kapena kupendekera pang'ono, kuwala kwa laser komwe kumabwerera kumalowetsanso mutu womwe umatuluka, ndipo ngakhale gawo la kuwala komwe kumabwerera kumaphatikizidwa mu ulusi wotumiza mphamvu, ndikubwezeredwa motsatira ulusiwo kupita mkati. ya laser, kupanga zigawo zikuluzikulu mkati mwa laser kupitirizabe kutentha kwambiri.

Pamene reflectivity ndi mkulu kwambiri pa kuwotcherera laser, njira zotsatirazi zikhoza kutengedwa:

3.1 Gwiritsani ntchito anti-reflection anti-reflection kapena kuchitira pamwamba pa zinthuzo: kuphimba pamwamba pazitsulo zowotcherera ndi anti-reflection anti-reflection kungathandize kuchepetsa kuwonetsetsa kwa laser. Chophimba ichi nthawi zambiri chimakhala chinthu chapadera chowoneka bwino chokhala ndi mawonekedwe otsika omwe amatenga mphamvu ya laser m'malo mowunikiranso. Munjira zina, monga kuwotcherera kwa otolera, kulumikizana kofewa, ndi zina zambiri, pamwamba pake imathanso kusindikizidwa.

3.2 Sinthani ngodya yowotcherera: Posintha mawonekedwe awotcherera, mtengo wa laser ukhoza kukhala wochitika pazinthu zowotcherera pamakona oyenerera ndikuchepetsa kuwunikira. Nthawi zambiri, kukhala ndi chochitika cha mtengo wa laser perpendicularly pamwamba pa zinthu zomwe ziyenera kuwotcherera ndi njira yabwino yochepetsera zowunikira.

3.3 Kuwonjezera wothandizira wothandizira: Panthawi yowotcherera, zowonjezera zowonjezera, monga ufa kapena madzi, zimawonjezeredwa ku weld. Izi zimayamwa mphamvu za laser ndikuchepetsa kuwunikira. Chotengera choyenera chiyenera kusankhidwa kutengera zida zowotcherera komanso momwe zimagwiritsidwira ntchito. M'makampani a batri a lithiamu, izi sizingatheke.

3.4 Gwiritsani ntchito kuwala kwa kuwala kuti mutumize laser: Ngati n'kotheka, fiber ya kuwala ingagwiritsidwe ntchito kutumiza laser kumalo otsekemera kuti muchepetse kusinkhasinkha. Ulusi wa kuwala ukhoza kutsogolera mtanda wa laser kumalo owotcherera kuti asawonekere mwachindunji pamwamba pazitsulo zowotcherera komanso kuchepetsa kuoneka kwa zonyezimira.

3.5 Kusintha magawo a laser: Posintha magawo monga mphamvu ya laser, kutalika kwapakati, ndi mainchesi apakati, kugawa mphamvu za laser kumatha kuwongoleredwa ndikuwonetsetsa kuchepetsedwa. Kwa zida zina zowunikira, kuchepetsa mphamvu ya laser kungakhale njira yabwino yochepetsera zowunikira.

3.6 Gwiritsani ntchito choboola chamtanda: Choboola chamtengo chimatha kutsogolera gawo la mphamvu ya laser mu chipangizo choyamwitsa, potero kuchepetsa kupezeka kwa zowunikira. Beam splitting zipangizo zambiri zigwirizana zigawo kuwala ndi absorbers, ndi kusankha zigawo zoyenera ndi kusintha masanjidwe a chipangizo, m'munsi reflectivity chingapezeke.

4. kuwotcherera undercut

Mukupanga batire ya lithiamu, ndi njira ziti zomwe zingayambitse kutsika? Chifukwa chiyani undercutting imachitika? Tiyeni tifufuze.

Undercut, zambiri kuwotcherera zopangira si bwino pamodzi wina ndi mzake, kusiyana ndi lalikulu kwambiri kapena poyambira amaoneka, kuya ndi m'lifupi kwenikweni wamkulu kuposa 0.5mm, okwana kutalika ndi wamkulu kuposa 10% ya weld kutalika, kapena zazikulu kuposa mankhwala ndondomeko muyezo kutalika anapempha.

Mu lonse lifiyamu batire kupanga ndondomeko, undercutting ndi zambiri zimachitika, ndipo ambiri anagawira kusindikiza chisanadze kuwotcherera chisanadze kuwotcherera yacylindrical chivundikiro mbale ndi kusindikiza chisanadze kuwotcherera ndi kuwotcherera wa lalikulu zotayidwa chipolopolo chivundikiro mbale. Chifukwa chachikulu ndi chakuti mbale yosindikizirayo imayenera kugwirizana ndi chipolopolo ku Welding, njira yofananira pakati pa mbale yosindikizira ndi chipolopolocho chimakhala ndi mipata yambiri yotchinga, grooves, kugwa, ndi zina zotero, kotero zimakhala zovuta kwambiri .

Ndiye chimayambitsa undercuting ndi chiyani?

Ngati kuwotcherera liwiro ndi mofulumira kwambiri, madzi zitsulo kumbuyo dzenje laling'ono kuloza pakati pa kuwotcherera sadzakhala ndi nthawi redistribute, chifukwa mu solidification ndi undercutting mbali zonse za kuwotcherera. Poganizira zomwe zili pamwambazi, tikuyenera kuwongolera magawo omwewo. Kunena mwachidule, ndikuyesa mobwerezabwereza kutsimikizira magawo osiyanasiyana, ndikupitiliza kuchita DOE mpaka magawo oyenerera apezeka.

2. Mipata yowotcherera yochulukirapo, ma grooves, kugwa, ndi zina zambiri za zinthu zowotcherera zidzachepetsa kuchuluka kwa zitsulo zosungunuka zomwe zimadzaza mipata, zomwe zimapangitsa kuti ma undercuts azitha kuchitika. Ili ndi funso la zida ndi zopangira. Kaya zowotcherera zopangira zimagwirizana ndi zomwe zikubwera za dongosolo lathu, kaya zida zolondola zimakwaniritsa zofunikira, etc. Mchitidwe wamba ndikuzunza nthawi zonse ndikumenya ogulitsa ndi anthu omwe amayang'anira zida.

3. Ngati mphamvu ikutsika mofulumira kumapeto kwa kuwotcherera kwa laser, dzenje laling'ono likhoza kugwa, zomwe zimapangitsa kuti pakhale kudulidwa kwapafupi. Kufananiza kolondola kwa mphamvu ndi liwiro kumatha kuteteza mapangidwe a undercuts. Monga mwambi wakale, bwerezani zoyeserera, tsimikizirani magawo osiyanasiyana, ndikupitiliza DOE mpaka mutapeza magawo oyenera.

5. Weld center kugwa

Ngati liwiro la kuwotcherera likuchedwa, dziwe losungunuka lidzakhala lalikulu komanso lokulirapo, ndikuwonjezera kuchuluka kwa zitsulo zosungunuka. Izi zitha kupangitsa kuti kusungika kwapansi kukhale kovuta. Chitsulo chosungunuka chikakhala cholemera kwambiri, pakati pa chowotchereracho chimatha kumira ndi kupanga madiresi ndi maenje. Pamenepa, mphamvu yamagetsi iyenera kuchepetsedwa moyenera kuti madzi asungunuke asagwe.

Munthawi ina, kusiyana kwa kuwotcherera kumangopangitsa kugwa popanda kuwononga. Mosakayikira ili ndi vuto la makina osindikizira oyenera.

Kumvetsetsa koyenera kwa zolakwika zomwe zingachitike pa kuwotcherera kwa laser ndi zomwe zimayambitsa zolakwika zosiyanasiyana zimalola njira yolunjika kuti athetse vuto lililonse lazowotcherera.

6. Weld ming'alu

Ming'alu yomwe imawonekera panthawi yowotcherera mosalekeza ya laser imakhala ndi ming'alu yotentha, monga ming'alu ya kristalo ndi ming'alu yamadzimadzi. Choyambitsa chachikulu cha ming'aluyi ndi mphamvu zazikulu zochepetsera zomwe zimapangidwira ndi weld isanayambe kulimba.

Palinso zifukwa zotsatirazi za ming'alu mu kuwotcherera laser:

1. Kupanga kopanda nzeru kwa weld: Mapangidwe olakwika a geometry ndi kukula kwa weld angayambitse kuwotcherera kupsinjika, potero kumayambitsa ming'alu. Yankho lake ndikukulitsa kapangidwe ka weld kuti mupewe kuwotcherera kupsinjika. Mutha kugwiritsa ntchito ma weld oyenera, kusintha mawonekedwe a weld, ndi zina.

2. Kusagwirizana kwa magawo owotcherera: Kusankha kolakwika kwa magawo owotcherera, monga kuthamanga kwambiri kuwotcherera, mphamvu yayikulu kwambiri, ndi zina zambiri, kungayambitse kusintha kwa kutentha kosafanana m'dera lakuwotcherera, zomwe zimapangitsa kuti pakhale kupsinjika kwakukulu ndi ming'alu. Yankho lake ndikusintha magawo owotcherera kuti agwirizane ndi zinthu zenizeni komanso zowotcherera.

3. Kusakonzekera bwino kwa kuwotcherera pamwamba: Kulephera kuyeretsa bwino ndikusamalira malo otsekemera musanayambe kuwotcherera, monga kuchotsa oxides, mafuta, ndi zina zotero, zidzakhudza ubwino ndi mphamvu za weld ndikupangitsa ming'alu mosavuta. Njira yothetsera vutoli ndikuyeretsa mokwanira ndikusamalira malo otsekemera kuti zitsimikizidwe kuti zonyansa ndi zowonongeka zomwe zili m'dera la kuwotcherera zimathandizidwa bwino.

4. Kuwongolera molakwika kwa kuwotcherera kulowetsamo kutentha: Kuwongolera kosakwanira kwa kutentha kwa kutentha panthawi yowotcherera, monga kutentha kwambiri panthawi yowotcherera, kuzizira kosayenera kwa wosanjikiza wowotcherera, ndi zina zotero, kudzachititsa kusintha kwa malo otsekemera, zomwe zimapangitsa kuti pakhale ming'alu. . Njira yothetsera kutentha ndi kuzizira nthawi yowotcherera kuti isatenthedwe komanso kuzizira kofulumira.

5. Kusakwanira kwa kupsinjika maganizo: Kusakwanira kwa chithandizo cha kupsinjika maganizo pambuyo pa kuwotcherera kumapangitsa kuti pakhale mpumulo wosakwanira wa kupanikizika m'dera lotsekemera, lomwe lingayambitse ming'alu mosavuta. Yankho lake ndikuchita chithandizo choyenera chothandizira kupsinjika mutatha kuwotcherera, monga chithandizo cha kutentha kapena kugwedeza (chifukwa chachikulu).

Ponena za kupanga mabatire a lithiamu, ndi njira ziti zomwe zingayambitse ming'alu?

Nthawi zambiri, ming'alu sachedwa kuchitika pa kusindikiza kuwotcherera, monga kusindikiza kuwotcherera ya cylindrical zitsulo zipolopolo kapena zitsulo zotayidwa zipolopolo, kusindikiza kuwotcherera a square aluminiyamu zipolopolo, etc. Komanso, pa ndondomeko ma CD ma module, kuwotcherera kwa wokhometsa panopa komanso sachedwa ku ming'alu.

Inde, tingagwiritsenso ntchito waya wodzaza, preheating kapena njira zina zochepetsera kapena kuthetsa ming'alu iyi.

Nthawi yotumiza: Sep-01-2023